FREQUENTLY ASKED QUESTIONS

Find answers to the most commonly asked questions about California Woodworking, Inc., our including design process, custom cabinetry, countertops, fixtures and more. If you have a question that isn't answered here, don't hesitate to contact us!

One of our most frequently asked questions is, when can you start? Our goal is to accommodate your schedule. Lead times vary depending upon the intensity of the order or project. Times may vary, however generally these are the time frames that can be expected:

Cut to size orders

- 3 business days

Full service cabinet and countertop service

- 5 business days for shop drawings

- 10-15 business days for fabrication (after drawing approval and field measurements are recorded)

Our goal is to accommodate your schedule to our best ability. Please contact us for a more realistic time frame for your specific project.

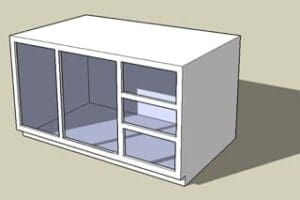

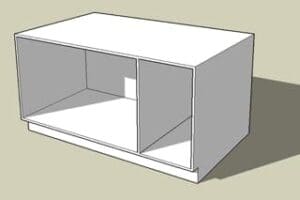

A face frame cabinet is similar to a frameless cabinet in construction where it is constructed with its sides, bottom and top, consisting of 3/4" thick material however a frame is constructed separately and attached to the cabinet face. A face frame is usually about 1-1/2" wide with its door being about 1" away from the cabinet side.

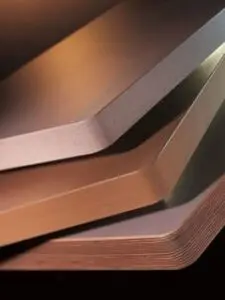

Edge banding is a finished material that is used on the exposed edges of cabinet components. PVC or Polyvinyl chloride is a very common plastic used to produce pipe, electrical cable, signs, clothing and furniture. PVC edge banding is available in a wide variety of colors and is engineered to match most high-pressure plastic laminate colors. PVC edge banding is most commonly used on frameless cabinetry where a face frame is not applied to the cabinet face. Thicknesses of PVC edge banding are most commonly .018" thick but are also available in .04" (1mm) and .12" (3mm) thicknesses.

High pressure laminate (HPL) is a combination of paper and resins pressed together under high pressure. High pressure laminate is most commonly manufactured from Formica, Wilsonart or Nevamar and is available in different colors, finishes and textures.

A sample of high pressure laminate is shown on the top surface of the sample. The vertical surface represents PVC edge banding. The core of the sample represents particleboard. Notice the HPL creates a black line on its exposed edge whereas the PVC does not.

A frameless cabinet is typically constructed with its sides, bottom and top, consisting of 3/4" thick material with its door edge being only 1/16" from the side of the cabinet. A frameless cabinet creates a more modern style and is also known as European style.

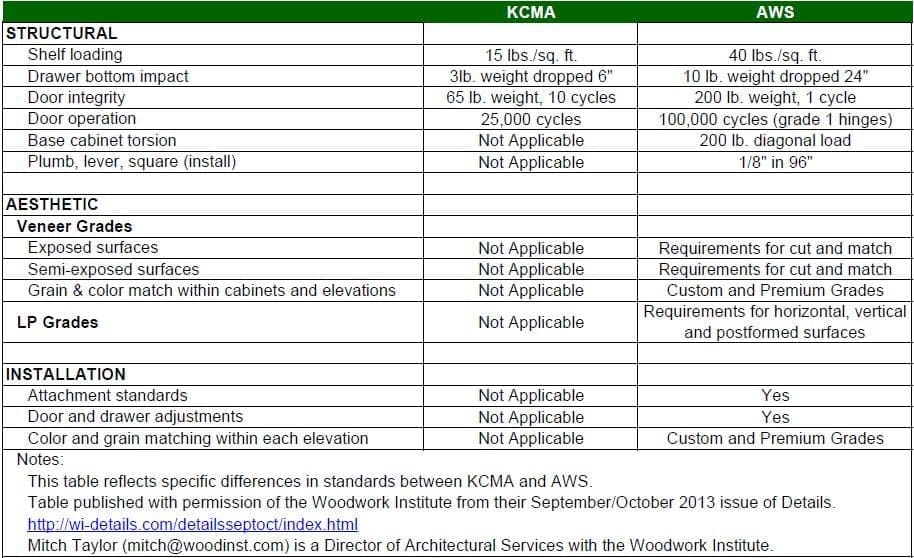

There are many specific differences in cabinet standards set forth by AWS and KCMA. The cabinet standards are listed in the table shown below.

Yes, California Woodworking, Inc. currently holds certification with the State of California as a small business (SB micro). You can click here for a current copy of our certification.

Both white oak and red oak lumber is most commonly categorized as plain sawn, quarter sawn and rift sawn. Although plain sawn is most common, both quarter sawn and rift saw oak creates a distinctive grain style due to the way the oak tree is sliced in relation to its medullary rays. Frank Miller Quarter Sawn Lumber (FrankMiller.com) explains the milling process that creates quarter sawn and rift sawn in oak lumber.

View Transcript

No

No

Yes, we custom fabricate and install all Corian name-brand acrylic countertops as well as similar name-brand acrylic materials like LX Hausys, Formica, Wilsonart, Durasein, Meganite, Basic, Avonite, Livingstone, and Bellavati.

Yes, we custom fabricate and install all Formica name-brand high-pressure plastic laminate countertops and similar name-brand high-pressure plastic laminate materials like Wilsonart, Nevamar, Pionite, Arborite, and Laminart.

No

We specialize in two different cabinet industries - commercial and residential. In the commercial cabinet industry, we fabricate a frameless-style cabinet also know as "European" style. In the residential cabinet industry, we are dealers for a variety of semi-custom face frame and frameless cabinetry which include Kraftmaid Vantage, UltraCraft, BJ Tidwell, Starmark, and Merillat Cabinetry.

No, we specialize in commercial and residential projects ranging from a small coffee bar cabinet in a commercial, office setting to a new kitchen cabinetry layout in a single-family residential home, or even a large apartment complex.

A die wall is a low-height wall usually used in an office setting. The die wall is the vertical structure that supports a countertop. The die wall and countertop usually form a desk assembly and are most commonly seen in a courtroom. Die walls are also used at a nurse's station in a hospital setting or at a reception desk in an office setting. The term "die" could have evolved from the original term "dais," which was a raised platform in a room used for speakers or special guests during meetings.

The main benefit of a wire chase within a die wall is to fully conceal all electrical conduits within the die wall. The main downfall of a wire chase within a die wall is the added cost and length of time required to create the wire chase and removable wall panels to access the electrical conduits for maintenance or troubleshooting purposes.

An alternate to providing a wire chase within a die wall is to request to have your electrical conduits and outlets surface mounted beneath the countertop where it will not be exposed to view.

Since there are so many different types and sizes of microwaves, a standard microwave size does not exist for kitchen within a commercial office space.

Yes, we welcome you to our showroom, where you can view physical samples of cabinetry, doors, hardware, and countertop materials. Our showroom is usually open Monday through Friday from 7:00 AM until 3:30 PM. We encourage you to call before arrival to ensure a team member is available to help answer your questions. We look forward to seeing you!

Have Additional Questions?

Please don't hesitate to ask!

Fill out our contact form and someone from our office will get back to you shortly.